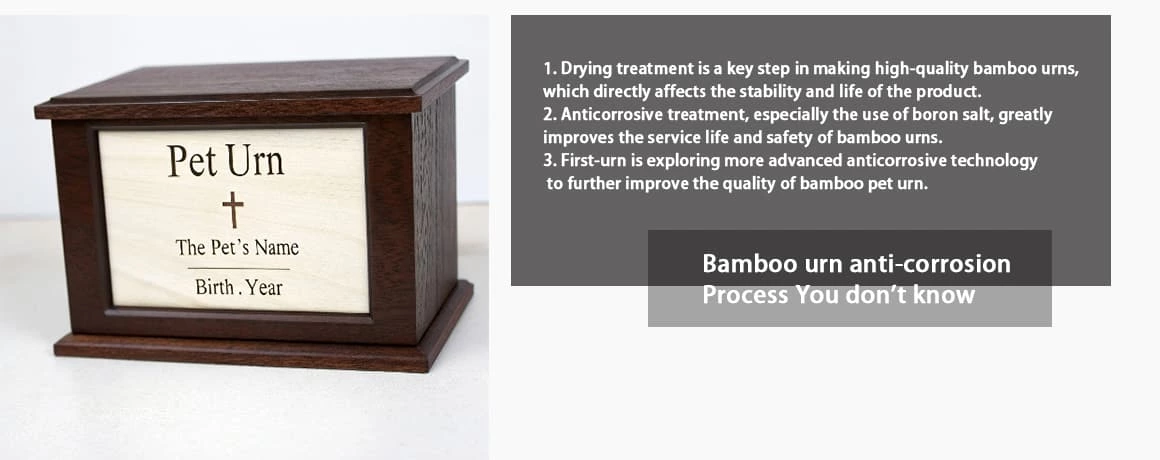

Bamboo urn anti-corrosion Process You don't know

Highly Kay Points

1. Drying treatment is a key step in making high-quality bamboo urns, which directly affects the stability and life of the product.

2. Anticorrosive treatment, especially the use of boron salt, greatly improves the service life and safety of bamboo urns.

3. First-urn is exploring more advanced anticorrosive technology to further improve the quality of bamboo pet urn.

In this era of environmental protection and personalization, bamboo urn is becoming the first choice for more and more pet owners. This article briefly describes the drying box anticorrosive process of bamboo urns, especially the innovative technology of First-urn in drying and anticorrosive treatment.

Drying treatment of bamboo urns

In order to the production of high-quality bamboo urn, then drying is a vital step. First-urn uses advanced drying technology to ensure that every bamboo urn can achieve the best water content.

Control the drying speed

First-urn's expert technical team, too fast drying can cause bamboo to crack, while too slow may cause mildew. Therefore, they carefully designed a phased drying system to gradually reduce moisture in bamboo and ensure the structural integrity of bamboo pet urn.

Constant temperature drying technology

By using a constant temperature drying chamber, First-urn ensures that every keepsake cremation urn is in an ideal temperature and humidity environment during the production process. This not only speeds up the drying process, but also effectively prevents the bamboo from deformation, laying a solid foundation for subsequent processing.

Quality monitoring

During the drying process, First-urn's quality inspection team will regularly check the water content of the bamboo. Only by meeting strict standards can we enter the next process. This rigorous attitude ensures that every bamboo urn has excellent quality.

Anticorrosive treatment of bamboo urns

In order to ensure that the bamboo urn can preserve the ashes of pets for a long time, embalming treatment is an indispensable step. First-urn's innovation in this area is particularly eye-catching.

Advantages of boron salt treatment

Boron salt has low toxicity, antibacterial, insect-proof, flame-retardant and other multifunctional properties, and has become the preferred anticorrosive material of First-urn company. This natural preservative is not only safe and harmless, but also can effectively extend the service life of bamboo pet urn.

Improve service life

Wood treated with a natural borate solution to protect against corrosion usually has a service life that is 5 to 6 times longer than untreated wood. This means that by choosing First-urn's bamboo urn, you can safely keep your pet's ashes for decades without worrying about damage to the box.

Both environmental protection and safety

keepsake cremation urn must not only be durable, but also environmentally and user-friendly. The boron salt treatment method they chose can not only achieve anticorrosive effect, but also will not cause a burden on the environment, truly achieving the perfect combination of environmental protection and practicality.

New measures for anticorrosive treatment in the future

First-urn has not just depended on exiting hard technology. We are actively exploring more advanced anticorrosive measures to further improve the quality of bamboo urn.

Biomass preservatives

In order to better respond to environmental protection needs, First-urn is developing a brand-new biomass preservative. This preservative is derived from renewable resources and can not only effectively protect bamboo pet urn, but also completely degrade after use without leaving any harmful residues.

Intelligent monitoring system

In the future, First-urn plans to implant miniature sensors in each keepsake cremation urn. These sensors will be able to monitor the status of the urn in real time and send maintenance reminders to users through the mobile app to ensure that the urn is always in the best condition.

What is the wood biomass preservative?

Wood biomass preservative refers to substances, often derived from biomass or bio-based materials, used to protect wood from biological degradation such as fungal decay, insect attack, and moisture damage. These preservatives can include bio-oils obtained from processes like fast pyrolysis of biomass, which impart antifungal and hydrophobic properties to wood, enhancing its durability and resistance to decay1.

Wood preservation broadly involves treating wood with chemical or biochemical agents to slow down or prevent deterioration caused by fungi, molds, insects, and other wood-destroying organisms. Biomass-derived preservatives are a subset of these treatments, leveraging natural or bio-based compounds to provide protection while aiming to reduce environmental and health risks associated with traditional chemical preservatives2.

Reference

- https://task34.ieabioenergy.com/preservative/

- https://www.sciencedirect.com/topics/materials-science/wood-preservation